If you know me, you know I love my shoes. Shoes are my kryptonite. I’ve always had a deep reverence for them since I was young. One thing I can’t stand is bad shoes—or dirty shoes. My family and friends have had to endure my critiques here and there whenever they possessed either of those.

Growing up, my mother was extremely entrepreneurial—she did everything. As much as I hated it then, I’m now grateful because it helped shape who I am today. Since I was a kid, my mum had several ventures. She ran a shop (which I probably sank with all the sweets I stole—sorry, Mum!), had an ice cream business (might have sunk that too), and made sweaters for sale. Our house was basically a factory; she had two knitting machines, and every evening, my siblings and I would come home from school and jump into the production line, stitching the sweaters together and adding beads. Everyone in the house had to finish a few before we could go to bed.

She also had a pawpaw business and even made me the accountant when I was five. But the venture I want to talk about is when she sold second-hand shoes. Every week, she’d travel to Mombasa to pick up a fresh bale of shoes, come home, open it, and then take it to the open market on Jogoo Road to sell. My job was to go to Jogoo Road after school, relieve the day seller, and wait for my mum. While there, I learned a ton about shoes. And even though I wouldn’t dare tell my schoolmates (who were busy watching Hulk and other cool shows after school), I had to sell shoes while doing my homework before heading home to stitch sweaters.

I was fascinated by shoes, though. I remember sitting there, examining their architecture and design, and falling in love with the thought process behind them. She eventually stopped selling shoes—I can’t remember why—maybe because I went to boarding school and she lost her free help. (For anyone thinking they can pay me in “exposure,” sorry, my mum already did a great job of that.)

After high school, I remember wanting a pair of shoes so badly but not having the money for them. The seller was asking for 600 shillings, and I only had 200. I paid the deposit and told him I’d come back the next day. That was probably the first time I used pure faith, hoping the shoes wouldn’t be sold. I went home, unsure of where I’d get the remaining 400, but I knew I *had* to have those shoes. I prayed about it, and guess what? Out of nowhere, someone reached out, asking if I could design some business cards for them. (I’d started designing on the computer in Class 8, so it came naturally, and I often did small designs for people for things like chips money.) They offered 500 shillings for the job! My prayers had worked. Needless to say, I designed the cards and earned myself the money for the shoes.

Years later, with my shoe game still on point, I began to wonder: what would it take to start a shoe brand?

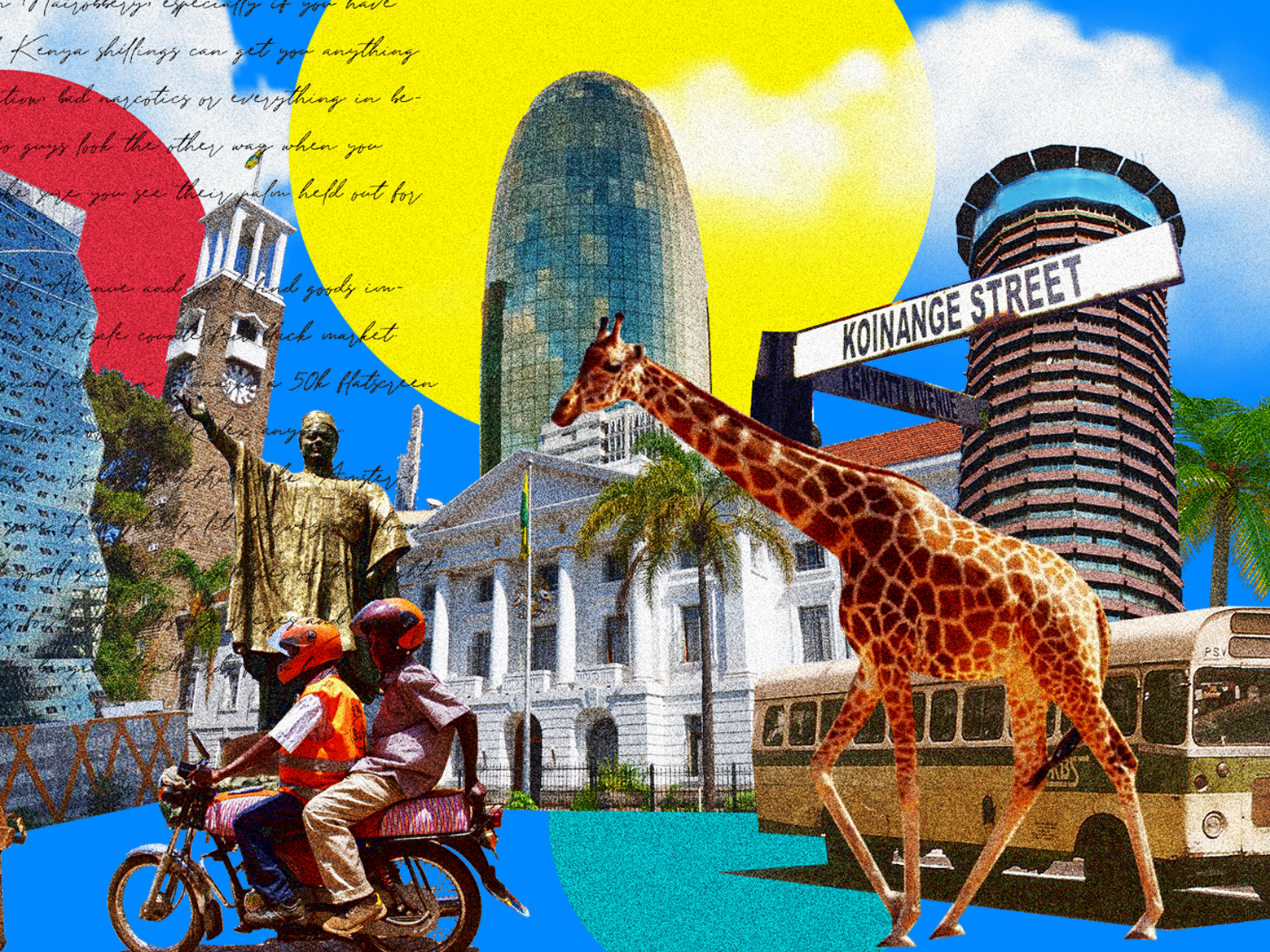

We at Creatives Garage decided to create a shoe but didn’t know where to start. When we looked around, apart from Bata, Leather Industries in Thika, and Maasai slippers, we didn’t see many other people or organizations making shoes locally. This raised so many "why" questions for us. For instance, we consume so many cows, so where does all the leather go? Why aren’t more people venturing into shoe production, especially when almost the entire population wears shoes?

Our minds were buzzing with too many "whys," so we decided to dig deeper. We aimed to explore the entire value chain of the leather industry—from blue wet leather to the final product. By following this chain, we hoped to uncover the challenges and bottlenecks in the industry. Our goal was to answer these questions by creating something tangible: a shoe made entirely in Kenya.

We got funding from the Netherlands Embassy in Nairobi and began research. First we put out a questionnaire and had about 200 participants. This is the information we collected. Through quantitative research, we gathered valuable insights. Here are the key findings:

From our desktop research on leather, these were our initial findings:

Kenya holds several advantages, such as being the fifth-largest economy in sub-Saharan Africa, possessing a well-educated labor force, advanced infrastructure, and a thriving financial services and information technology sector. However, the country faces challenges like trade imbalances, a weak currency, and limited value addition in certain industries.

The leather industry in Kenya has significant untapped potential. Despite Africa having a substantial livestock population, it only produces 4% of the world's leather. If Kenya processed and manufactured leather into products like shoes, its value could increase twelve-fold. Currently, only a small percentage of Kenya's leather exports are in the form of footwear, handbags, and other leather products.

The creative industry as a way to tackle unemployment and contribute to Kenya's industrialization. As Creatives Garage, our goal is to build ecosystems that provide creatives with access to markets, positioning Kenya as an industrial hub.

A study conducted by the Ministry of Industrialization and Enterprise Development recommends promoting industry restructuring, improving access to markets, and enhancing quality and standards across the value chain to strengthen the leather industry.

Kenya enjoys cost advantages and preferential access to global markets, making it an attractive sourcing destination. However, its market share in the textile industry, particularly in the U.S., remains low. There is an opportunity to expand market share, enter new markets, and develop higher-value products, leading to GDP growth and job creation. The 2009 export tariff on raw hides and skins has shifted the focus toward value addition within the leather industry.

Simply put, Kenya’s potential in footwear manufacturing is massively underutilized. Footwear can be ethically and sustainably produced within Kenya’s industrial sector at lower costs than importing. Kenyan-made shoes account for only 12.5% to 16.67% of the market share, with an annual need for between 24 to 32 million pairs of shoes. Currently, local production stands at around 4 million pairs.

Foreign brands like Nike, Vans, Puma, Converse, Clarks, and Giuseppe dominate the Kenyan footwear market, especially in the high-end demographic. Nairobi consumers overwhelmingly prefer leather for locally-made shoes. Despite this, Kenya’s leather industry relies heavily on exporting high-quality leather, with wet blue leather primarily sold to China. Finished leather products, such as shoes, handbags, and travel goods, accounted for $9.17 million USD out of $146.73 million USD in total leather exports in 2013.

The Kenyan market receives lower-end leather products, while the best-quality goods are exported. With tariff rates differing significantly between semi-finished and fully-finished imports, the local market is at a disadvantage.

So, why weren’t we manufacturing shoes in Kenya?

Blue leather at Leather Industries in Thika

Thanks to the support of the Embassy of the Kingdom of the Netherlands in Nairobi, we were introduced to an organization called PUM. PUM matches businesses with experts from the Netherlands to advise on how to improve their operations. Our interest in this program was to understand shoe making from a global perspective, as we envisioned that the Shoejaa Shoes would need to adhere to world-class standards for quality production.

Through this exchange, we were introduced to Theo Verbunt, who has been in the shoe industry for 40 years. His expertise includes shoe production and trading across a global network.We took Theo everywhere—Kariokor, Leather Industries Thika, Toi Market, and high-end shops in the malls. After a thorough walk-through of the production capabilities of the partners we were working with—artisans from the informal sector and Leather Industries of Kenya—Theo gave us a candid and practical view of the sector.

His conclusions were eye-opening:

"The Kenyan shoe industry has practically come to a total halt. It’s not even certain, but there could be only 2 or 3 factories still operating.”

"Imports of cheap footwear have grown to such overwhelming volumes from China and other South Asian countries at such low prices that the Kenyan footwear industry didn’t stand a chance of competing. Even high import duties didn’t protect the local industry.”

"Kenyan suppliers of materials necessary for the shoe industry— leather, soles, insoles, laces, glue—have almost disappeared.”

Meanwhile, we were trying out a few artisans who could stitch shoes for us and here are some of the samples we got.

Stitched locally but we couldn't find soles because only one place in Kenya produces soles but my order was too few for a sole design.

Upon recognizing the need to streamline production and address the challenges we faced, we decided to explore the development of a policy paper that could be presented for legislation. To guide us through this process, we sought the expertise of our lawyer, who provided valuable insights.

Our lawyer explained that transforming an idea into a draft bill and ultimately passing it as legislation involves a complex and lengthy process. Here is a simplified illustration of the stages involved:

The Production

After realizing that our initial production partner was incapable of delivering our shoe designs, we encountered various challenges in finding a suitable manufacturer. The factory in Thika, which we had initially partnered with, had limited production capacity and could only manufacture the upper part of a shoe, primarily focusing on working boot uppers. They were unable to produce the desired soles for our Shoejaa Shoe line.

We also discovered that the artisans at Kariakor market, who had helped us create the first prototype (1.0), lacked the expertise to translate our designs into the type of shoe we envisioned. Their craftsmanship did not meet our quality standards, and we doubted their ability to mass-produce the shoes. As a result, we sought out another local shoe maker named Dan, who operated from a stall in a market in Nairobi's Eastlands area. Although Dan demonstrated good craftsmanship and could manufacture the updated designs, the production process was time-consuming, taking two months just to obtain the samples. Continuing to work with Dan to produce even small quantities would result in lengthy production times.

Faced with these constraints, we explored alternative production options. We initially attempted to establish partnerships with production plants in Ethiopia but faced challenges due to unresponsiveness. Following insights from Theo about production capabilities in India, we shifted our focus there. I traveled to New Delhi to meet a few manufacturers at a leather conference. However, the manufacturers exhibiting were quite costly, making it economically impractical given the market demand for a cost-effective shoe. Consequently, we redirected our focus to sourcing production in China.

I flew to Guangzhou without knowing anyone or where to start, but I figured staying at one of the fancy hotels might help since they would likely have English speakers who could direct me. I arrived in China, exhausted from hours of flying, checked into my hotel, and after freshening up, went downstairs to ask for guidance. They directed me to a place with thousands of exhibition shops. Little did I know that Google isn’t available in China, which meant I couldn’t use Google Translate or WhatsApp, making communication extremely challenging. I had to rely on a translation app provided on their phones.

After several frustrating conversations that hit dead ends, one guy finally pointed me in the right direction. When I got there, I found floors upon floors of manufacturers.

Our efforts in China paid off, as we discovered several factories capable of producing the designs for our Shoejaa line with the desired materials for the uppers and soles. However, many of these factories required a minimum order of 1,000 pairs just to produce samples. Luckily, we connected with a manufacturer who was willing to work with us on a smaller scale, requiring a minimum order of 100 pairs to produce the samples.

Working with this manufacturer, we were able to finalize the production of the shoes for the market. The uppers are made of high-quality cow leather, ensuring durability and aesthetic appeal. The inner soles consist of memory foam, providing an ergonomic fit, moisture-wicking properties, and comfort. The outsoles are made of direct injection rubber, offering durability and functionality.

In summary, despite encountering challenges and exploring various options, we successfully found a manufacturing partner in China who could produce the high-quality and aesthetically pleasing Shoejaa shoes that meet the demands of the market.

The shoe we wanted to create needed to carry significance. So, we called the brand Shoejaa, a blend of 'shoe' and 'shujaa,' meaning warrior. To honor a true Kenyan hero, we chose Syokimau as the first name for our shoe, thus creating the Shoejaa Syokimau edition.

Who is Syokimau?

This edition of the Shoejaa shoe was inspired by Syokimau who was a great visionary, a badass woman with major skills.

Syokimau served as a spiritual leader in the Akamba community, where her role was to pray and offer sacrifices on behalf of the warriors before they embarked on cattle raids. In times of calamity, such as plague outbreaks, she was the go-to woman for intercession.

She is remembered for her remarkable achievements, including being a renowned medicine woman and prophesying the coming of colonialists and the railway.

Syokimau’s legacy is so profound that an area in Kenya is named after her, and it remains to this day.

Shoejaa is a shoe that though not manufactured in Kenya it was designed in Kenya. After several sketches I did, I eneded up with what we currently have. I wanted a shoe any sex could wear and I think this shoe fits that criteria. The vamp is made from quality cowhide leather, the insole from latex and the sole from EVA.

EVA sole is different from Rubber sole. EVA (Technically named Ethylene Vinyl Acetate) is one of the best shock absorption materials available today.

The overall result is a quality shoe product influenced by our dynamic ethnicity that we are proud to be a part of.

It is unfortunate that we were not able to fully create the shoe here. Even more unfortunate that we sell our locally produced leather as blue leather to Chinese factories that end made making the most money from the finished product while we still earn very little from our raw materials. Shoejaa was in high demand, we sold 90% of the shoes in the first month of shipping them back to Kenya. I hope the leather industry can scale up and the bottlenecks within the system will be sorted out soon. Meanwhile, who is ready for our second Shoejaa

design?